News

CONCORD, AND THEN?

Article published in Lettre 3AF N°2-2024

by Jean Pinet, former Concorde test pilot

February 4 2010: Jean Pinet receives the Gold Medal from the Aéro-Club de France

Arts et Métiers 1949, Supaéro 1952 - Armée de l'Air 1952-1956, Fighter pilot (USAF)1954 - Centre d'Essais en Vol 1956-1965, INE 1957, Testpilot 1958, missile tests - EStelle der Bdw 1962 - 1965, missiles on F104G- Sud-Aviation/Aérospatiale 1965-1994 - Concorde program 1965-1985, Airbus Industrie 1972-1994 - Aeroformation (Airbus Trng today)1972-1994, founder, airline pilot instructor - Docteur en psychologieergonomie 2011 - Académie de l'Air et de l'Espace 1984, member and former president 1989-1991 - Membre émérite 3AF 2002.

An old question, with no clear or satisfactory answer. It was asked as soon as the airplane entered service nearly half a century ago, and for a long time there were only proposals for an answer. Then, 20 years after Concorde's commercial demise, the crystal ball began to shatter, and it was time to ask for an opinion on the future of supersonic transport.

This is an interesting intellectual exercise with a random success rate. In the classic way, reasoning is based on past experience, observed trends and estimates of their evolution. It also includes current events to stimulate curiosity.

THE PAST

Concorde opened up a flight domain, but not a market.

It was the answer to mankind's irresistible goal: to go further, faster and higher. This was made possible by the unprecedented gamble of two European governments who, 60 years ago, wanted to make this goal a reality, together and for their peoples.

This Franco-British initiative, launched during the "glorious 30s" following the Second World War, paved the way for the European collaboration in civil aeronautics that we have enjoyed ever since.

Despite a shaky international organization, hundreds and thousands of people rushed to make this insane project a reality: comfortable daily crossings of the Atlantic at over 2000 km/h for a hundred or so passengers in their everyday clothes.

The result was a beautiful aircraft that carried half a million people for 27 years. There was one accident, the causes of which have been demonstrated to be extremely improbable according to our current regulations, on which Concorde is based.

This adventure, for it was one, mobilized resources that today astonish our young engineers by their frugality: slide rule, punched-card computer, drawing board, ground layout of structures, analog simulation, and more. We had to invent, innovate, change, modify, try out, validate, always fast, despite the hazards and constraints of organizational structures. And it worked. The concrete objective, the Concorde aircraft, progressed thanks to the motivation of all involved.

Adventure and motivation! Concorde was a real technical feat, and remains a global benchmark.

However, only 14 aircraft were operated commercially, mainly between Europe (London and Paris) and the USA (New York and Washington). Few elsewhere.

Commercial operations

From the outset, the lure of speed and innovation led airlines all over the world to reserve options on future production aircraft - 76 (or 74?) in all. By 1973, however, rising oil prices and development costs - due to the need to explore an unknown flight envelope and develop solutions to match - had an impact on operating prices, forcing potential customers to withdraw their options. Only national airlines remained in the running, as the aircraft was subsidized by both governments. The financial problem was the argument for withdrawal.

However, another event later played an important role in the decision to cease operations, independently of the accident. The low number of aircraft in service made it impossible to amortize the cost of replacing the aircraft's analog equipment with more reliable digital equivalents. Maintenance and replacement costs were becoming prohibitive.

However, the 27 years of operation of the 14 aircraft had proved the feasibility of supersonic service, albeit at high cost and in a marginal field given the globalization of subsonic transport, but with experience of its advantages and limitations.

On the move

Right from the start of operations, problems were analyzed[1] and the "team" in place proposed possible improvements. The commercial appeal of supersonic aircraft was widely believed at the time, and there were plans for 250-seat aircraft with extended ranges. However, development and operating costs - linked to compliance with new standards - remained a stumbling block, as the trend was resolutely towards mass transport in the upper subsonic range, with operating costs well below those of improved supersonics.

The "big ones" were abandoned in favor of "business" supersonic projects, which required less investment, and whose clientele was more affluent than that of conventional subsonic transport. This too was abandoned.

It should be noted that in addition to the problem of cost, there was the technical and financial problem of an engine suitable for both low-speed take-off and landing, and supersonic speeds, for which no one wanted to embark on a costly development project, without any valid estimate of a positive financial return.

The environment

Environmental issues had not yet been raised in 1962. Only the fear of damage to the ozone layer. Environmental protection soon came up against a number of obstacles. The limited number of aircraft in operation, and therefore subject to criticism, was a factor in the acceptance of the nuisances caused by the use of the 14 Concorde aircraft. Because they were limited, they were tolerable.

On the other hand, if the number of supersonic aircraft became significant, their successors would find it difficult, if not impossible, to break free from the regulatory limitations of civil air transport, especially the environmental ones. Exemptions would probably be necessary, but difficult to obtain.

TRANSPORTUPERSONIC FEATURES (2)

Here, we only mention those that differentiate it from subsonics, showing where the problems lie if we want to continue in this field.

60 years ago, there was no experience of supersonic transport. Today, the operation of Concorde has provided us with knowledge that increases our chances of moving towards supersonic flight, albeit with new constraints that tend to slow down progress.

Operational use

In air transport, aircraft are the result of compromises between commercial needs and technological realities, the two fields being closely linked in the competition of costs and markets. Observing the way in which aircraft are used operationally, where the particularities of an aircraft reflect its adaptation to the market, and where symmetrically the market takes into account the technical constraints of air transport, gives a fairly clear idea of the complexity of the necessary choices.

Supersonic flight brings its own technical and operational specificities, defining the limits of a particular market within the dominant subsonic transport market.

Here are just a few, drawn from Concorde's unique experience.

- To go supersonic, you have to go subsonic, as the two don't have exactly the same constraints (air density, gust and turbulence, fatigue, flutter, temperature, variation in the position of the aerodynamic center with Mach number[3], pressurization, meteorological phenomena), nor the same rate of airspace use. Hence the different operational limitations. Aerodynamic speed (here conventional speed Vc for simplicity's sake) is a major parameter in defining the aircraft's structure. In supersonic flight, Vc can be higher than in subsonic flight. Concorde's operational limit was 400 kt in subsonic and 520 kt in supersonic.

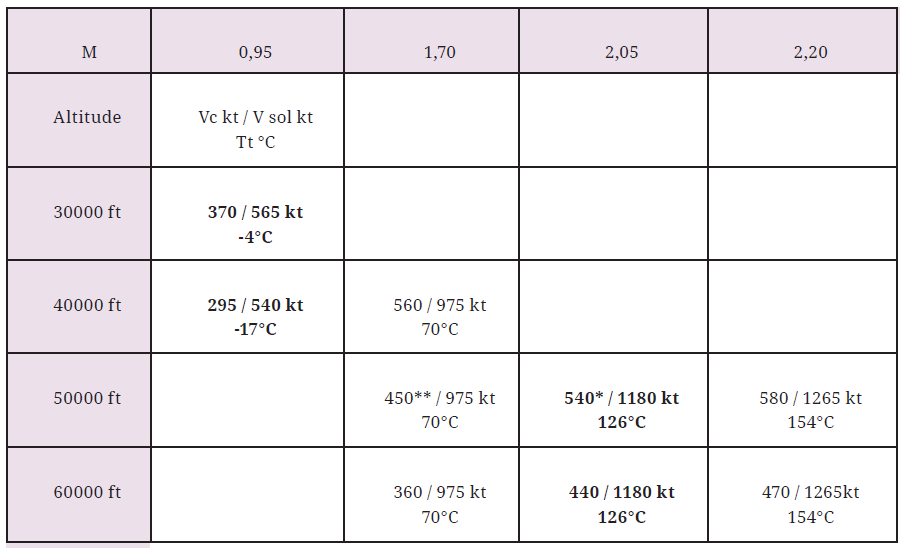

A table in the appendix gives a few points in the flight envelope where a supersonic aircraft could be placed.

- Concorde's operational limitations - VMO speed (maximum operating speed), MMO Mach (maximum operating Mach), TMO temperature (maximum operating temperature) - fell within the optimum range for speed, range and fuel consumption. Consequently, the need to optimize performance meant that the aircraft was used operationally at its limits (e.g. engines running constantly at maximum rpm, inlet temperature 126°C), which subsonics rarely do.

This use of engines and equipment at their operational limits had a direct impact on operating costs.

- In the low-M area of the flight envelope, up to about M 1.50, the combination of supersonic disturbed flow, high dynamic pressure with high Vc, and the flexibility of the wing structure, led to sharp reductions in flight control surface efficiency.

- As the aircraft flew at its propulsion ceiling, the load shedding effect of high fuel consumption enabled a continuous rise in altitude at constant M, thus reducing specific fuel consumption.

- The drop in the aerodynamic center of thrust during supersonic flight meant that the aircraft's center of gravity had to be shifted aft, thanks to fuel transfer. This drop in the center of gravity at cruise speed meant that the aircraft would have been longitudinally unstable at low speeds, hence the need to transfer fuel forward during subsonic deceleration.

- The impact temperature, a direct function of M, increases rapidly, as shown in the attached table. This increase is not homogeneous across the structure, with the lower surface of the wing being hotter than the upper surface (skin temperature around 100°C), which, together with the influence of dynamic pressure, causes significant deformation of the wing and fuselage, leading to fuel tank leaks, among other consequences.

- As the impact temperature was high, it was necessary to eliminate the flow of heat transmitted by the aircraft's surfaces, as well as calories from electronic systems, air-conditioning units and engine lubrication. Fuel from the fuel tanks was also used for cooling, before being burned in the engines.

- Motorization was complex, and we should refer to it as a powertrain in which, to simplify, there were three parts: (1) the air intake, allowing the air to slow down before the engine, (2) the engine, (3) the nozzles controlling the ejection jet. These three interdependent components were operated together. At M 2, for example, the control of Concorde's inlet shock waves was directly linked to that of the engine. Air inlet pressure efficiency was 0.93 to 0.96.

- Weight is the key parameter in any project. The payload (passengers and freight) and the fuel required for the mission are superimposed on the empty weight, which is the object of all concern. This empty weight, defined at the outset of the project, has the pernicious tendency to increase as the definition of the aircraft is refined and the results of flight tests are obtained, which generally leads to an increase in the fuel required for the mission, or a reduction in the payload.

- The interdependence of all the technical and operational parameters is such that the supersonic aircraft is optimized for a defined maximum mission, at the end of which the expected limitations of the systems come into play. In the case of Concorde, for example, which was designed to fly between Paris or London and New York, the limit of supersonic flight was reached when the fuel could no longer ensure longitudinal balance or equipment cooling, and subsonic flight became compulsory.

- The advantage of speed over the evolution of time as perceived by passengers was obvious on westbound flights, but much less so on eastbound flights, where time was "compressed". On the Paris-New York route, for example, the load factor, close to 100% westbound, was halved eastbound. The problems of flight schedules and aircraft programming were tricky to work out.

- An example of technical/commercial interaction: at low speeds and on initial climb, the combination of aircraft incidence and trajectory gradient caused the fuselage floor to tilt, preventing internal movement.

- On the other hand, flying at over 50,000 ft in an uncongested area means that direct spherical trajectories - segments of great circles - can be used.

- The only significant meteorological disturbances in the stratosphere during a flight are those of temperature, which have a direct influence on M. Wind, on the other hand, is weak, with little influence on performance.

However, there are major temperature differences between polar and tropical zones, with significant variations in tropopause altitude. Similarly, during a flight with a propulsion ceiling, a variation of just a few degrees can lead to significant trajectory disturbances.

In subsonic flight, the aircraft suffered from the same problems as subsonic aircraft.

To ensure that flight time was not penalized by fog on arrival, Cat III landing qualifications were mandatory.

- The fuselage windows were small in order to limit the speed of pressure drop in the event of a rupture, as the emergency descent in the event of depressurization to 60000 ft would take five minutes.

- In the end, this type of operation was limited to transporting those who could afford a ticket costing several times more than first class on a subsonic aircraft: wealthy customers, professionals and politicians in a hurry, supersonic tourists.

STATE OF THE ART

Environmental constraints

- Noise on takeoff and approach.

Like Concorde's engines, today's supersonic engines, all of them military, are designed for the high ejection speeds required for supersonic flight. A high bypass ratio would be required at low speeds to attenuate jet noise, hence the need for an engine with these two opposing characteristics. The consequences are an increase in air intake area (drag) and mass.

The acceptance of Concorde's particular case at New York-JFK was due to the guarantee of trajectories avoiding noise detectors, thanks to the aircraft's exceptional handling qualities.

- The sonic boom.

Speed acceleration beyond M 1, for example in a climb, causes shock waves to focus on the ground, greatly amplifying (x 5 to 10) the sonic boom associated with the Mach number M of uniform straight-line flight, which could be tolerated. Its perception on the ground and its amplitude depend on the winds and temperatures between the ground and the aircraft's altitude, and on the latter's weight and altitude. Prediction is not straightforward: for example, a flight at M 1.7 could cause a bang of greater intensity than one at M 2.0.

It is therefore necessary to have a zone for acceleration where focusing is tolerated, e.g. above the sea.

Note that this focusing also occurs in turns, whatever the M of supersonic flight.

Today, most countries prohibit supersonic flight on their territory.

- Air pollution.

The effect on the ozone layer has not been confirmed.

Nox pollution from engines is declining.

That of condensation trails is a topical issue. For supersonic aircraft, flying at their propulsion ceiling for reasons of optimum propulsion efficiency, contrails in the upper atmosphere, above 12 km altitude, are poorly understood.

Carbon monoxide pollution (CO2) is unavoidable, because for a long time, fuel for supersonic aircraft can only be kerosene or similar, such as Sustainable Aviation Fuel (SAF), for reasons of maximum energy density in limited volumes. Weight and aerodynamic drag impose their requirements, thus eliminating the use of hydrogen.

Targets for decarbonization and limiting the greenhouse effect must now be met.

Note that fuel consumption per passenger in supersonic flight is bound to be much higher than in subsonic flight, as drag due to shock waves is an inescapable reality.

The technology

Today's technology offers partial solutions to the above-mentioned problems, some of them costly. For example:

- Among other things, the air impact temperature determines the temperature of the fuselage and wing structure, and hence the choice of materials. At M 2.20, it is 154°C; at M 2.05, as for Concorde, it is 126°C; lower down, at M 1.70, it is 70°C. We can see, for example, that the use of composite materials can be conditioned by the chosen speed, or vice versa.

Lightweighting thanks to these materials, which is actually quite low, depends on the size and shape of the structures. It can also be partially offset by the need to metalize the fuselage to protect it from lightning strikes.

- Fly-by-wire controls and digital equipment technology offer a host of operational possibilities, while also reducing weight. But we mustn't forget that they also generate calories that need to be eliminated.

- Some equipment and systems currently used in subsonic transport could already be integrated without major modifications.

However, we need to be wary of the chronic underestimation of adjustments required by real-world aircraft testing and certification.

The methods

Those used or in the process of being used in the aeronautics industry provide the basic support needed to run a supersonic project, with the possibility of coordinating in real time all the companies and people involved in complex studies and actions. The extensive possibilities for calculation, simulation and shared use of data significantly reduce the risk of error, and to a lesser extent the time needed to obtain the final results, where human expertise remains indispensable for orientation and choice.

Modern computing resources and the use of artificial intelligence as a tool do not negate the need for physical models and test benches.

Note that for a new supersonic project, the same methods and means will be used as those used or planned for a new subsonic aircraft project of equivalent size, with additional loads:

- when the aircraft is not an extension of achievements whose experience we can benefit from;

- the problems specific to supersonic aircraft, mentioned above;

- and the difficulty of starting from scratch in terms of organization and resources, if the manufacturer is inexperienced in these methods and resources.

This adds both delays and risks to projects.

Much of the savoir-faire of yesteryear acquired thanks to Concorde has faded with the disappearance of the actors, and whatever the performance of today's and tomorrow's tools - artificial intelligence, machine learning and the like - a learning curve for the people using them will be necessary.

Certification

The wide flight envelope of the supersonic aircraft, with its much higher speeds and altitudes than the usual subsonics, and its particular environmental characteristics, leads to the addition of specific certification procedures, including those already adopted for Concorde. It would not be impossible for the FAA and EASA authorities to apply exemptions adapted to actual operating conditions.

IS SUPERSONIC TRANSPORT STILL A POSSIBILITY?

"Going faster, further, higher" is written in the genes of mankind. However, we have the impression that, in this race, air transport remains stuck in the subsonic domain, leaving space to satisfy this quest? Concorde did demonstrate that we can go faster and higher in safety, but not very far. Should we leave it at that?

Which market?

Supersonic transport (Tsp) offers several advantages over subsonic transport (Tsb).

The undeniable attraction of speed is only one element reinforcing a choice based on practical considerations. The reduction in journey time is the essential positive element, under certain conditions, including acceptance of the cost.

In view of the above, the price of the trip is bound to be higher than that of a standard First Class flight in subsonic transport (Tsb). On the other hand, if the difference is not too great, and is accompanied by particular comfort, it is certain that supersonic transport (Tsp) can appeal to a proportion of First and Business class travellers. It's hard to estimate the number of people who are affluent and opportunistic in their choice of transport, but it's possible to do so today. The global air transport situation and its problems are well known, whereas they weren't in 1960.

For this Tsp, which in the next few decades will only be marginal compared to the Tsb, technical choices - shape, speed, structure, number of passengers, weight, fuel, engines, systems - will be defined by adaptation to a few main trade routes. For other routes, flexibility will be the order of the day, as the aircraft will have to adapt, with the disadvantage of lower operating performance.

It is assumed that the rules on decarbonization and protection against the greenhouse effect, applied by the Tsb, will also be respected by the Tsp.

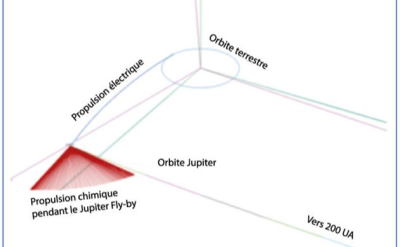

Supersonic flights over inhabited areas will only be possible with exemptions, which the EASA and FAA authorities would not grant today. Even if the X59's tests give positive results, it's hard to see how such a long nose could be operationally adopted on a Tsp. On the other hand, the oceans offer large operational surfaces, especially the Pacific. In the latter case, to avoid long-distance stopovers, the aircraft would have to be qualified for at least 10,000 km (5,400 nm).

Of course, at the heart of a project and for the chosen routes, the essential problems of timetables and connections, at the start and finish, need to be solved in order to take advantage of the speed differential between the Tsp and Tsb, the reason for the Tsp's existence.

As we saw earlier, the profitable operation of supersonic aircraft is inherently more difficult than the more flexible operation of subsonic aircraft.

Societal acceptance

A project of this magnitude, involving both industry and air transport, and entailing risks both in the aircraft's design and in its commercial success, can only see the light of day if it meets with a minimum of support from the society in which it is created, with financial backing coming above all from industrial companies rallying around the project.

In Europe today, we're a long way from the political impetus and state funding that launched Concorde in 1962. Despite the disappearance of the early players, there is still a wealth of experience available, thanks to the two airlines that used the aircraft, and the design offices that made progress from the Concorde era onwards. The enormous potential skills available throughout the European aeronautical industry, not just at Airbus, could be put to good use on a Tsp project. But in Europe, society is mired in societal-psychological constraints, in the precautionary principle, and above all in ecological dogmas impervious to logic, leading it to reject air transport a priori. It's hard to say when we'll be rid of them. For the time being, the industry is focusing on saving energy and replacing kerosene. Given Europe's low spontaneous motivation for innovation, it would seem inappropriate to speak of a more fuel-hungry Tsp than a Tsb on the road to economy, even if the objectives of decarbonization and greenhouse effect reduction were met.

The situation looks better in the USA. First of all, it's likely that the American aeronautical world would be in favor of taking up the challenge once imposed by the European Concorde. This world is used to risk, and failure is not necessarily a disgrace. Technological and financial possibilities superior to those in Europe would make a project based on a serious technical and commercial study credible, and quantifiable today. Military interest cannot be ruled out. Such a project would be carried out in a climate of positive motivation for innovation, as progress in the space sector has proved.

China's interest, and that of Japan surrounded by seas, cannot be ruled out.

Photo taken at Mach 1.6 over the Irish Sea by a Tornado, Dario Leone

ORGANIZATION AND DECISION-MAKING

This is a difficult part of the Tsp breakthrough, as the flying zones are explored, and current technology and design and manufacturing methods make it possible to solve most of the existing problems.

For such high-risk, high-funding projects, a group of partners seems to be the solution. On the other hand, the dissimilar experiences of Concorde and Airbus clearly demonstrate the need for a single decision-making authority with the technical, commercial and organizational skills required to bring the program to a successful conclusion, right through to operational service.

A major problem is that of defining the stages and their chronology. Keeping to deadlines in a program that is a priori fraught with hazards is difficult, but essential. Optimism about deadlines, later contradicted by foreseeable or unforeseeable delays - a classic method when trying to attract investors - leads to a decline in the program's credibility, with negative consequences.

CONCLUSION

Supersonic transport represents an evolution in the human quest for "faster, farther, higher". However, human beings also expect benefits that compensate for the efforts made, while respecting environmental rules that didn't exist 60 years ago.

The knowledge, the technical means, a small but quantifiable market, the possibility of raising financial resources - all of this exists to resume the course of supersonic flight. But launching a Tsp project also requires the firm motivation of the parties involved, responding positively to the question: "Is it worth the risk? Such motivation is hard to find in Europe, which is subject to dogmatic ecological political pressure.

But it is possible elsewhere.

CASE OF THE "OVERTURE" BOOM

Can we estimate the project's credibility?

The Boom project remains the only one in the running of the three American projects presented in 2014, Aerion and Spike having been abandoned.

Initially, the project was for an aircraft flying at M 2.20 with 45 to 50 passengers. A 1/3-scale demonstrator, XB-1, whose configuration is so far removed from that of the latest project presented in 2023, was due to fly in 2017 but did not take off in 2023.

The project presented is now that of an aircraft, "Overture", flying at M 1.70 with 64 to 80 passengers, powered by a new "Symphony" engine also developed by Boom, whose worldwide operation would be profitable.

Will this aircraft be the second supersonic transport?

Examination of the limited information provided by the aircraft manufacturer (in 2023) suggests that the project should be technically feasible, Concorde having largely paved the way. But it also suggests that, as presented, Boom would not be able to pull it off.

Here we'll try to estimate the positive points and foreseeable obstacles.

This estimate can only be made credibly on the basis of experience acquired on subsonic aircraft, transposed to the resolution of known supersonic problems. This experience covers all aspects: technical, commercial, financial and environmental. Obviously, the estimate can be modified by concrete information as the project progresses.

INFORMATION PROVIDED BY BOOM

There are only a few, and these are just targets for potential customers, with no figures to guarantee them. Apart from the Mach, which drops from 2.20 to 1.70, performance hasn't changed since the first project in 2014. The only thing that has changed is the way the vehicle and its 4 engines look.

Flying area

Supersonic flight over land is not envisaged. On departure and arrival, part of the flight will therefore be subsonic, probably around M 0.95.

The "target" supersonic cruise performance is M 1.70 at an altitude of 60000 ft.

The maximum advertised range of 4250 nm (7860 km) allows access to a number of major cities, many thanks to a subsonic flight section. Normal fuel reserves are assumed. 600 possible connections are announced.

Fuselage

Designed for 64 to 80 passengers.

The advantage of an all-composite structure is mentioned.

Engine

Symphony is a dual-flow engine with a medium bypass ratio, designed to solve the problems of noise and adaptation to different take-off and cruise speeds, and to comply with the regulations imposed, in particular Chapter 14 of the ICAO noise standards.

Take-off thrust would be 35,000 lb (16,000 daN).

The engine is new both in terms of configuration and manufacturer. The advantage of 3D printing in manufacturing is highlighted.

Lifetime extension of 25% and cost reduction of 10% compared with current supersonic engines (military only) are expected.

The fuel will be SAF.

Prices and advertised costs

Aircraft and engine development and certification: $6 billion

Plane: $200 million without interior fittings.

Round trip London-New York: $5,000.

Initial financing doesn't seem to be a problem.

Partnership

Partnership contracts were signed (by the end of 2023) with 11 companies to design, manufacture and equip the aircraft, and with 2 companies to design and manufacture the engines.

Deadlines

First flight with Symphony engines is scheduled for 2027, with certification in 2029 and commercial launch in 2030.

POSITIVE POINTS AND FORESEEABLE OBSTACLES

Commercial appeal

M 1.70 is a compromise between commercial appeal and technical difficulty.

M 1.70 is equivalent, above the troposphere, to 975 kt or 1810 km/h, i.e. twice the speed of today's subsonic aircraft, giving a tangible speed advantage over long distances.

Current air transport networks in oceanic areas are well known, and offer opportunities with the expected range, sometimes with an intermediate stopover. However, the figure of 600 possible connections seems optimistic. We assume, as Boom assures us, that the conditions for decarbonization and the fight against the greenhouse effect will be met for the airplane to be accepted worldwide.

The chances of capturing a share of the subsonic First and Business class market are a direct function of the price differential with these classes, the departure and arrival times at the place of operation, combined with any connections, and secondarily of particular comfort.

Hence the absolute necessity for the manufacturer to control costs (investment, design, testing, manufacturing, training, fuel, maintenance) and define the routes on which the aircraft will be optimized.

Project home

The airlines' enthusiasm is reminiscent of that which accompanied the Concorde project at the time: 130 options for three airlines, two American, UAL and AAL, and one Japanese, JAL.

An important positive for the project's future is that NASA and the US Air Force are interested, via a cooperation with Northrop- Grumman on a research program.

The first commercial flight is scheduled for 2030, which is a challenge for Boom, as you can see below.

Flying area

The cruising operating point, M 1.70 and 60,000 ft, corresponds to a Vc of 360 kt. Vc is an essential parameter for structural calculations, and defines one of the limits of the flight envelope.

This raises the question of the value of the maximum operational Vc, VMO (possible between 350 and 600 kt), in acceleration and climb to reach M 1.70 and 60,000 ft.

This initial part of the flight and cruise obviously depend on aerodynamic characteristics, weight, the chosen VMO, and powertrain performance, which we don't know except for the Symphony engine's ground thrust target.

The impact temperature is 70°C, instead of 154°C at M 2.20, simplifying the problems of heating and thermal stress, as composite materials are used for the structure.

The maximum range, a key element of the project, depends on parameters such as aircraft weight, glide ratio, aerodynamic drag, specific fuel consumption and fuel mass, all of which are unknown to us. We know that the compromise between these essential parameters is a delicate one. Are they defined today?

Compliance with the law of areas favors drag reduction. Despite the great potential of available computing resources, only flight test results will be able to guarantee the distances involved, with normal fuel reserves. Will performance guarantees be given in the traditional way 5 years before delivery to the customer?

Powertrains

Boom's decision to design and manufacture the engine, called Symphony, is one challenge. Hoping that there will be 4 engines in operation on the aircraft by 2027 is another, as the development time for a major engine manufacturer to produce an equivalent-class engine derived from an existing type is in excess of 5 years.

Each of the 4 engines will be housed in a nacelle under the wing. This nacelle will have to be adapted to ensure smooth operation of the dual-flow engine (high master-torque) and control of air inlets and nozzles throughout the flight envelope, including take-off and cruise. It will be more complicated and heavier than a subsonic nacelle.

Program management

It's all about the interweaving of technical, organizational and financial problems, the outcome of which will be the success or failure of the program. We have very little information on these subjects, but an analysis of this little, based on experience and the current state of aeronautics, leaves no room for optimism for the current program as presented.

In a nutshell:

Boom must simultaneously develop, manufacture and certify an entirely new aircraft, its entirely new engine, and adapt them to a field of use in which the aircraft manufacturer has no experience, by 2029, the scheduled certification date, in 7 years.

Despite the expected power of IT resources, we can assume that the time and resources required will be no less than those available today for medium-haul subsonic programs, benefiting from the experience of previous models and, in particular, the availability of systems integration and flight simulation test benches well in advance of the first flight.

Financing

The figure announced for aircraft and engine development, manufacture and certification is $6 billion. This is at best half the current cost of launching a subsonic medium-haul aircraft. So it's a challenge to secure the necessary funding for an aircraft that has to be entirely "reinvented" by an organization starting from scratch.

Partnership contracts, accompanied by possible financial participation, could guarantee real financing with project loyalty and risk sharing.

Organization

These are just estimates. There seems to be a centralized design office of fairly few people, working on pre-projects for 10 years or more. Today, when it comes to realization, their number seems to be well below what would be necessary for a subsonic aircraft program, led by personnel already experienced in the whole aircraft, its motorization and its systems.

The aim seems to be to compensate for the shortage of staff and the need to reduce lead times, by making intensive use of integration methods, current IT tools for rapid information exchange, and simulation. The necessary skills seem to be acquired through partnerships with specialist companies.

But in this type of participative organization, where it is necessary to specify, coordinate and continuously check the feasibility and performance of complex systems in their interconnected operation, permanent coordination is required at all levels of intervention.

Working on virtual models can simplify exchanges, but cannot replace adjustments on real models and test benches by competent personnel in sufficient numbers.

Manufacturing can be aided by 3D printing or other proven new processes.

Coordination, choices and decisions would be made within the Boom design office.

It should not be forgotten that validation is necessarily carried out on actual physical elements, and flight tests sometimes call into question uncertain choices.

In short, the difficult project starts from scratch, quickly, with a seemingly insufficient number of competent staff, and a reliance on IT tools to compensate for weaknesses.

The prediction that the aircraft will be ready for certification in 2029 is unrealistic from what little information is available, since it takes 5 years to develop a high-performance subsonic aircraft whose general architecture and systems are merely extrapolations of those of existing aircraft.

Motivation is there, but it's not enough. The USA shows us that new companies can rapidly design and manufacture innovative equipment. Space X is a good example, with one important detail: there were no humans on board, so failures were not catastrophic.

CONCLUSION

The certification authorities are certainly monitoring the program and advising the manufacturer of potential certification hurdles. It could even be argued that the FAA would have to relax a number of conditions for the project to succeed, for example with major regulatory concessions on environmental limitations, particularly noise.

But it's also doubtful that the administration is very tolerant today.

The will to succeed is not enough. From what little information is available, the technical and financial resources appear to be significantly inadequate to solve the known problems, not to mention the unforeseen.

Overture and its Symphony engine are a challenge, and the chances of certifying a product that achieves advanced performance within the timescales and funding announced, seem nil according to our current references.

So let's wait for more information.

1st flight of the 02 with Yves Pingret, Jean Beslon,

Jean Pinet, Claude Durand and Jean Franchi.

APPENDIX

SOME OPERATING POINTS

In bold Concorde area

* Exactly with a VMO (maximum operating speed) of 520 kt we had M 2.05 at 52000 ft, otherwise we would have stayed at M 2.00 reached at 50500 ft.

** M 1.70 can be achieved at 55000 ft with a Vc of 400kt.

1 - Dossiers de l'AAE: n°3 "L'avion de transport à haute vitesse, Recommandations", 1991; n°19 "L'avion de transport supersonique, Journée d'étude à l'ONERA 6 avril 2000", 2002.

2 See AAE Dossier 46 "De Concorde aux nouveaux projets d'avions supersoniques", Gérard Théron.

3 - In the following text, the letter "M" will be used for "Mach number".

No comment

Log in to post comment. Log in.